No products in the cart.

Articles

3D ‘Bioprinting’ Could Help With Child Heart Defects and More

July 11, 2022 – Nearly 1 out of each 100 youngsters within the United States are born with coronary heart defects. The results will be devastating, requiring the kid to depend on implanted units that have to be modified over time.

“Mechanical solutions don’t grow with the patient,” says Mark Skylar-Scott, PhD, a professor of bioengineering at Stanford University. “That means the patient will need multiple surgeries as they grow.”

He and his staff are engaged on an answer that might present these youngsters with a greater high quality of life with fewer surgical procedures. Their thought: Using 3D “bioprinters” to craft the tissues docs want to assist a affected person.

“The dream is to be able to print heart tissue, such as heart valves and ventricles, that are living and can grow with the patient,” says Skylar-Scott, who’s spent the previous 15 years engaged on bioprinting applied sciences for creating vessels and coronary heart tissue.

The 3D Printer for Your Body

Regular 3D printing works very similar to the inkjet printer at your workplace, however with one key distinction: Instead of spraying a single layer of ink onto paper, a 3D printer releases layers of molten plastics or different supplies separately to construct one thing from the underside up. The consequence will be absolutely anything, from auto components to total homes.

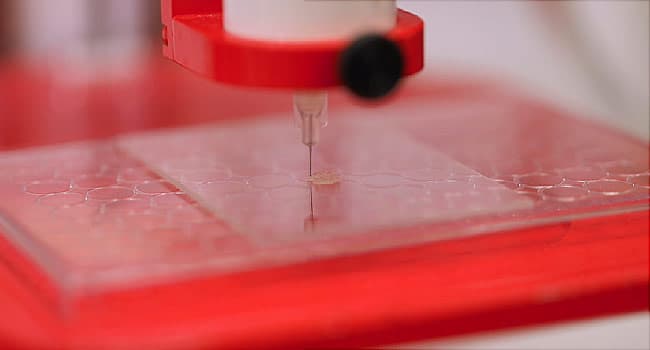

Three-dimensional bioprinting, or the method of utilizing dwelling cells to create 3D buildings reminiscent of pores and skin, vessels, organs, or bone, appears like one thing out of a science fiction film, however the truth is has existed since 1988.

Where a 3D printer could depend on plastics or concrete, a bioprinter requires “things like cells, DNA, microRNA, and other biological matter,” says Ibrahim Ozbolat, PhD, a professor of engineering science and mechanics, biomedical engineering, and neurosurgery at Penn State University.

“Those materials are loaded into hydrogels so that the cells can remain viable and grow,” Ozbolat says. “This ‘bio-ink’ is then layered and given time to mature into living tissue, which can take 3 to 4 weeks.”

What physique components have scientists been capable of print thus far? Most tissues created via bioprinting to this point are fairly small – and almost all are nonetheless in several phases of testing.

“Clinical trials have started for cartilage ear reconstruction, nerve regeneration, and skin regeneration,” Ozbolat says. “In the next 5 to 10 years, we can expect more clinical trials with complex organ types.”

What’s Holding Bioprinting Back?

The hassle with 3D bioprinting is that human organs are thick. It takes a whole lot of hundreds of thousands of cells to print a single millimeter of tissue. Not solely is that this resource-intensive, it’s additionally vastly time-consuming. A bioprinter that pushed out single cells at a time would want a number of weeks to provide even just a few millimeters of tissue.

But Skylar-Scott and his staff lately achieved a breakthrough which will assist considerably reduce on manufacturing time.

Instead of working with single cells, Skylar-Scott’s staff efficiently bioprinted with a cluster of stem cells known as organoids. When a number of organoids are positioned close to one another, they mix – much like how grains of rice clump collectively. These clumps then self-assemble to create a community of tiny buildings that resemble miniature organs.

“Instead of printing single cells, we can print with bigger building blocks [the organoids],” Skylar-Scott says. “We believe it is a quicker way of manufacturing tissue.”

While the organoids pace up manufacturing, the following problem to this fashion of 3D bioprinting is having sufficient supplies.

“Now that we can manufacture things with a lot of cells, we need a lot of cells to practice,” says Skylar-Scott. How many cells are wanted? He says “a typical scientist works with 1 to 2 million cells in a dish. To manufacture a big, thick organ, it takes 10 to 300 billion cells.”

How Bioprinting Could Change Medicine

One imaginative and prescient for bioprinting is to create dwelling coronary heart tissue and complete organs to be used in youngsters. This may scale back the necessity for organ transplants and surgical procedures because the stay tissues would develop and performance together with the affected person’s personal physique.

But many points must be solved earlier than key physique tissues will be printed and viable.

“Right now we are thinking small instead of printing a whole heart,” Skylar-Scott says. Instead, they’re targeted on smaller buildings like valves and ventricles. And these buildings, Skylar-Scott says, are not less than 5 to 10 years out.

Meanwhile, Ozbolat envisions a world the place docs might bioprint precisely the buildings they want whereas a affected person is on the working desk. “It is a technique where surgeons will be able to drag the print directly on the patient,” Ozbolat says. Such tissue printing expertise is in its infancy, however his staff is devoted to bringing it additional alongside.